I plead ignorance.

I plead ignorance.When a friend watched me set both the iron and the wedge on one of my handmade planes with a metal mallet, he said "You're supposed to use a wood mallet to tap the wedge and plane body."

"Yeah. Well, I sort of like the tool marks on the

backs of my planes," I insisted.

backs of my planes," I insisted.He gave me a look that said he knew I was bluffing; that I really had no idea you should switch mallets mid-adjustment.

I've been abusing my planes this way for years and they have the half moon marks to prove it. I've even all but obliterated my name on one of them.

Little wood mallets come in handy for more than just plane adjustment

s. They're also helpful with driving in & removing the wedges from tusk tenons, and joining dovetails & finger joints. And it was high time I made one.

s. They're also helpful with driving in & removing the wedges from tusk tenons, and joining dovetails & finger joints. And it was high time I made one.The element that's lost in small wood mallets, though, is weight on the hammer end. So I chose to make the handle from cherry and the hammer head from rosewood. Rosewood is heavy and dense, which can damage a project in use, so I decided to buffer the blow with cherry pads glued to each end.

I referred to a tack hammer's handle as a template, rough cut the blank on the bandsaw, and finalized the shape with a sanding drum chucked into my drill press.

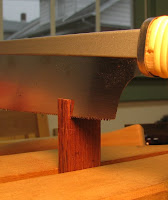

A wedged through-tenon is an effective way to secure the hammer head to the handle. First, drill a hole at the lower end of the tenon so it won't split when you drive the wedge in. Then saw a kerf down the middle of the tenon.

The 6th photo shows the [slightly] loose-fit tenon that provides wiggle room for the wedge. Cut the wedge with your tool of choice; I used a Japanese dozuki. Add glue to the tenon, mortise, and wedge, and then hammer the wedge home.

Two cherry pads and three coats of Watco Wipe On Poly later, and my wood mallet and handplanes are playing nicely together.

And I can finally remit my H.A.A. (Handplane Abusers Anonymous) member card.

19 comments:

Hi Kari,

Take not a scrap of notice.

It really doesn't matter if you use a metal hammer to adjust a wooden plane. On the old-time wooden jacks and other larger bench-planes, there was a 'very-hardwood' button sunk into the front of the body at which to aim your hammer! Some makers even added a similar button to the back end of the body. Others didn't.

However, a few 'french-blow' marks in the back end of the plane meant nothing and didn't affect the useage.

It's nice to use a wooden mallet, but we aren't exactly going to use a club-hammer and all out bodyweight are we? So if you prefer a metal hammer (which is more precise as it happens) then you use one and to heck with the 'naysayers'!

Regards

John

Kari,

I am constantly amazed at the amount of work you turn out! Nice mallet.

John, I hope my friend reads your comment. ; )

Thanks, Vic!

Hey Kari,

Beautiful job, instead of sanding on the drill press, try a spoke shave and card scraper. I have done a few handles like this and it works great and no dust.I don't even rough them out. And yes, you amaze me with your work ethic and everything you get done.

Hi Kari - hope you had a good Christmas. I've always been meaning to make on of these sorts of tapometers (or Birmingham screwdriver in the UK!)but I use a small nylon headed mallet instead which seems to work quite well...though a nice little deadblow in ebony or African Blackwood might be on my 'tuit' list for the New Year - Rob

What a sweet little hammer. How the heck am I going to get any of my own turned into wood if you continue putting "I gotta make me one of those" ideas in front of me?

Cheers --- Larry

I totally agree with Larry. It is such a beautiful hammer and I've been needing just such a precision adjusting tool for my maple smoother. It's now on the want to build list.

I have some pics of the smoothing plane on my blog.

Keep up the great work Kari!

Now we know how you spent Xmas Day! Beautiful work.

MontanaMark, you're absolutely right---there is something ironic about making a handtool with power tools.

Rob,I'll look forward to seeing your handsome tapometer in future. I'd love to get ahold of some African Blackwood sometime. It's gorgeous.

Larry, at least this is a project you can make in an evening. ; )

Joe, nice job on your handplane! I have one maple plane that works better than the others. I think in part because the wood hardly moves at all.

Mark, I can't think of a better way to spend the holidays. haha

.

I’m often drawn to your blog and entertained by it’s slightly off-beat slant – it’s very refreshing.

Your new project is a very nicely executed little hammer, but I must pose the question, ‘Why use a mallet on the wedge of a plane?’

Going back to basics, wooden planes have been in almost constant use for a couple of thousand years and reached a state of perfection long ago where iron adjustments were carried out quickly and easily at the bench.

I grew up using wooden planes and I was taught that the wedge secures the iron in use and prevents it moving up or down in the plane’s throat by friction alone.

Downwards pressure on the wedge from the heel of the hand should provide sufficient friction to hold the iron in place, but allow it to move during adjustment.

This way the iron can be adjusted by advancing and retarding its bedding in the throat with nothing more than light taps with a mallet on the nose or the toe of the plane, as appropriate. The old workers could adjust the cut of a plane precisely and quickly with just a few light taps – but not on the wedge!

It strikes me that if the wedge needs persuasion with a mallet, then it is a poor fit on the iron and attention should be given to a clean bed contact between the flat or the wedge and the top face of the iron.

If the wedge were intended to be struck with a mallet, would the crown of the wedge not be a more amenable shape to be struck?

A nicely curved wedge head fits the palm better than a glancing blow with a mallet. Then, how do you get it out if it is driven home tightly?

Sorry to post this, but that’s the way wooden planes are intended to work, as I was taught.

..

A very nice mallet Kari!

I usually adjust my wooden planes with the same small brass hammer I use for fretting dulcimers. If that isn't handy I reach for my wooden bench mallet.

I've never hit a plane or iron hard enough to cause any significant marring though it would certainly class up my shop to have as lovely a mallet!

Cheers,

Doug

Solidrig, thanks for the comment. I have no rebuttal; I can only say that I use a mallet to adjust the wedge because that's the way I was taught.

And you're right that the wedge should not be pushed or knocked in so tightly that you can no longer adjust the depth of cut with a light tap to the back or front of the plane body. I lightly tap the wedge in place—just enough to hold the iron.

I'll have to give your technique a try. Which might mean I have another useless mallet on hand!

Thanks Doug!

Solidrig, I enlisted the help of Larry Williams, of Clark & Williams planes, to answer your question. Here is Larry's response:

While hand pressure alone should be able to hold an iron in place, I prefer a light tap on a wedge to secure things. I find tapered irons require less wedge pressure than irons of a uniform thickness. I think this is the big advantage of tapered irons. It doesn't take much taper in the length of the iron to work with the opposing wedge taper. Having the wedge of a single iron bench plane release unexpectedly is a safety issue. There's nothing to prevent a single iron from dropping out the mouth of a bench plane if the wedge releases pressure.

Applying too much pressure to the wedge is probably the most common cause of difficulty in setting wedge adjusted hand planes. I think the advantage of setting wedges with a light tap of a mallet is the distinctive feel and sound of a properly seated wedge. The sound a feel of a well fitting wedge finding home provides a reassuring feed-back you don't get from hand pressure alone. That kind of feed-back is one of the big advantages of wooden planes and I try to find it in each step.

Larry

.

Thank you – that’s very interesting and thank you to Larry for the time taken in replying.

Actually I’m a plane user, - not a maker – so I’ll yield to a source of greater knowledge.

Re-reading what I wrote I realised that I inadvertently omitted to mention fettling the planes, which may have made more sense of what I said.

In my experience of old planes that I sometimes resurrect to another life, fettling is essential - that’s obvious, though some folk never fettle their tools and put them to work straightaway.

In general it is a matter of doctoring the sole and applying the edge of perfection to the blade. I never assume that the wedge and iron are a good marriage, just because they lie in the same bed.

But I’ll venture that with wooden planes, moulding planes and the like, there’s a little more to it. With a newly acquired plane, I start with dismantling, cleaning and giving the body a good soak in linseed oil – that can take a week or two – and once the thing has acclimatised, the sole gets the attention it deserves.

Next the iron; I should add that as well as flatting the back I always flat the top (bevel side) where it is in contact with the wedge. Often, with Victorian tools in the UK, there are undulating forge marks on the top of the iron that can compromise the secure bed of the wedge and this was the thrust of what I meant earlier.

After this, with the wedge and iron assembled loosely I can check the fit of the wedge. A wipe of carbon paper on the iron shows any high spots on the wedge.

A wedge that sits evenly on the face of the iron throughout its length needs less pressure to remain firm and when pushed home, exerts its force in a straight line along the body of the plane, resulting in less stress on the plane body and the positive bedding action that Larry was referring to.

A wedge that has an insecure seat can transfer forces from a mallet at an odd angle to the bed of the iron and may distort the cheeks of the plane – apart from the danger of the iron popping out in use.

I have used this technique for most of my woodworking life - a bit long winded, I’ll admit, but you only need to do a major fettle once.

But, ultimately, success is what works best for you and I admire your gifted work.

.

Solidrig, thanks for sharing your process for fettling. :o)

Thanks for posting the photos of your mallet. When I showed them to my wife my five year old wanted to see as well and then wanted one made for him as well. (His three year old brother preferred to have one bought instead of made.) On Saturday I spent some time making two mallets out of scraps of walnut and hard maple.

The boys then spent the afternoon banging on scraps and having a good time with them.

Thanks for the inspiration.

Take care,

Jared

Jared, what a great gift for kids! I bet your boys had a good time whacking away at wood that afternoon. Thanks for sharing--it made my day.

:o)

Kari, I love the mallet and want to make one myself. My question is, how did you attach the "cherry pads" to endgrain on either end of the head?

Happy New Year!

Mitch

Mitch they are glued end grain to end grain. Surprisingly, it holds. I've done it before on other projects and years later, nothing's fallen apart. :)

Post a Comment